My Dad's Dance Floor Project

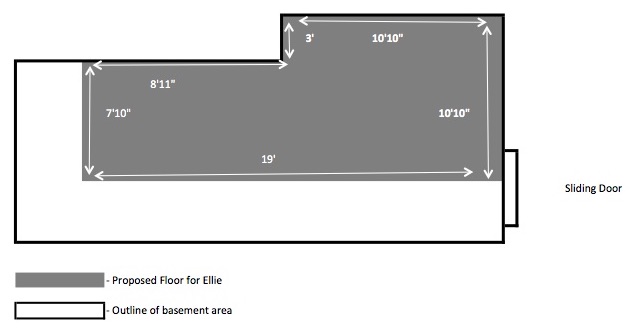

Our dance floor was to be constructed over a concrete floor in a walkout basement room. It was to be used by our Level 6 ballerina for her practice and possibly future teaching. The project outline is shown below:

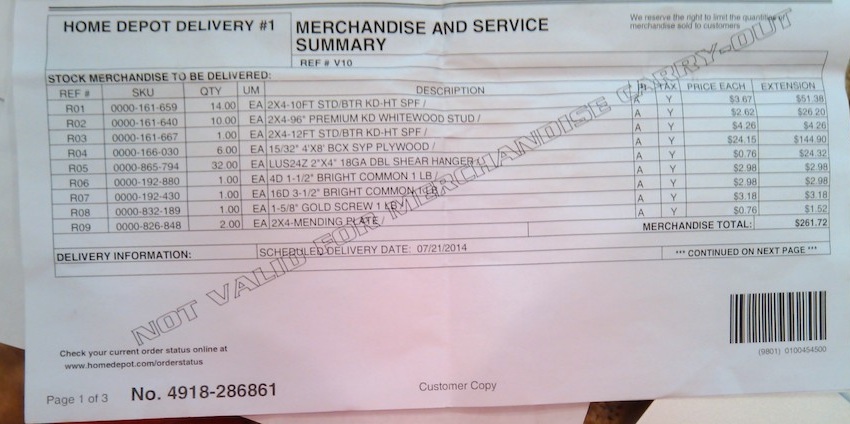

The frame was constructed of 2x4s, 16” on center. The first step was to build the box frame, which would enclose the 2x4 joists. The joists were attached to the box frame using joist hangers, one could probably have just nailed each joist into the frame and saved a few $$ on the hangers. Our floor size was essentially two rectangles – 10’4” x10’4” and 10’ x 8’. We built each frame separately and let the plywood floor top provide the connection between the two frames.

After constructing the two wood frames with joists, we then attached the foam blocks to the bottom of the completed frame. We used about 450 blocks for the entire floor which put about 2-3” between each 3x3 block. In hindsight we probably could have separated them by 4-5” and reduced the number of blocks while increasing the springiness of the floor a bit more. However, the floor does have enough “give” to be on par with the studio floor our ballerina uses. We purchased the blocks on-line from Foam N’ More Inc.. Their product is called Minicell and is sold in sheets but they will cut to size and attached an adhesive on the back of each block.

Once the blocks were attached (Highly recommend buying foam blocks pre-cut and with adhesive pre-applied) we place each frame box on the floor and proceeded to screw the plywood onto the top of the frames. We used premium BCX plywood with a finish that had no knots or blemishes. If you go with the cheaper stuff, those knots will show through the final flooring material.

Plywood in place, we investigated the various final flooring options available. Dance floor companies will sell you coverings that will cost well over $1000 for our square footage plus shipping. Many people have reported success with PVC shower pan liner and rubber roofing materials. Most have reported that 40 -50mil thickness is preferred. We compared samples from dance floor companies with rubber roofing samples (EDPM) and PVC shower pan liner, and our student preferred the PCV covering over the rubber roofing material. Relative costs are $256 for a 10’x50 roll of .045” (45 mils), Allegro (dance company) flooring @ $7.40/sqft, and PVC shower pan liner @ $168 for a 5’x40’, 40mil roll. The best prices for rubber roofing material are at a roofing supply store. The best price for PVC liner we found was at Home Depot.

PVC shower pan flooring is laid directly on the plywood with no adhesive required, except at any seams. The material lays flat and will not move over the plywood floor. If you want to tape the edges for a more secure fit, you can; but for ballet it works just fine as is. The Oatey brand we used is slightly less wide than the advertised width (by about 1”) and while there is only writing on one side (the side that faces the plywood), there is some ink transfer to the “upside” when the material was first made and coiled into a roll. Not visible enough for us to want to try and remove it, but others have done with cleaning supplies and some scrubbing.

The end result is a solid but flexible dance floor comparable in quality to a dance studio at a very reasonable cost.

Material costs for Dance floor (10’x10’ + 8’x10’) 180sqft.

| Description | Cost |

|---|---|

| Framing and plywood floor | $261 |

| Floor covering – Oatey PVC 5’x40’ roll | $168 |

| Seam and duct tape | $20 |

| 480 EVA foam blocks 3”x3”x3/4” w/adhesive | $100 |

| Total | $559 |